No Time to Read?

Let’s Explore the Blog Together to Know What’s Inside in 5 min summary video

Previously we clarified how United nation consider electrical energy is a key solution for global climate change,how electricity is cleanner than fossil fuels, and how it can release deadly power resulting in serious damage or loss of life when by faulty contact with conducting material, machines, equipment or human being.

Four main hazards are identified

Read ``Fundamentals of Electrical Safety at work pt.1``

Control Measure

Similar to other types of workplace hazards and risks, national and international laws and regulations require employer to set out adequate control measures for electrical hazards and risks to prevent fatal and not-fatal injuries. Although electricity is deadly, it can be controlled through by proper precautions.

Generally safety rules and precautions circle around:

- The proper design, installation and maintenance of electrical systems,

- Safe work activities and protective equipment.

- The strength and capability of electrical equipment

- Means of protection against hazardous environments

- The suitability of electrical connections

- Means for protection from excess current

- Precautions for working on dead or live conductors

- Workspace safe environment

- Work force competency requirements

Adminstarive roles regarding safe electrical activities

Whether having manager or supervisor responsibilities, your major duty is to ensure safe work without health risks and all workers follow the safety rules and control measures identified in risk assessments

a) Managers

– Setout system of safety rules and procedures through brief policies statement for securing the isolation, working dead or live and simple safe work instructions.

– Ensure competency of electrical works contractors following standards, rules and procedures.

– Ensure awareness of task-specific risk assessments including each member in the team.

– Provide Safety rules that clearly indentify Worker’s limitations.

– Provide fully detailed procedures for safe working on particular task, machine, equipment

– Periodically review policies, rules, instructions, procedures of the work.

– Ensuring competency of team workers through training programs

– Keep communication channels open to workers to report any change of work system

b) Supervisors

– Participate in planning the electrical work and risk assessment process.

– Coordinate ongoing electrical works specially where many groups involved

– Discuss safety electrical precautions and emergency procedures with workers

– Clearly define the roles and responsibilities of team leaders regarding elecrical works

– Coordinate work with electric works subcontractors

– Assign tasks to competent electricians

– Supervise how work is going safely, instruct newcommer and young workers

Do your work with pride, put safety in every stride

– Safety Advisor

Safety precautions of electrical activities

Some equipment operates at low-voltages, despite electric shock unlikely to occur, arcing, burns and explosions can occur in explosive atmosphere.

1. Safety precautions of electrical activities

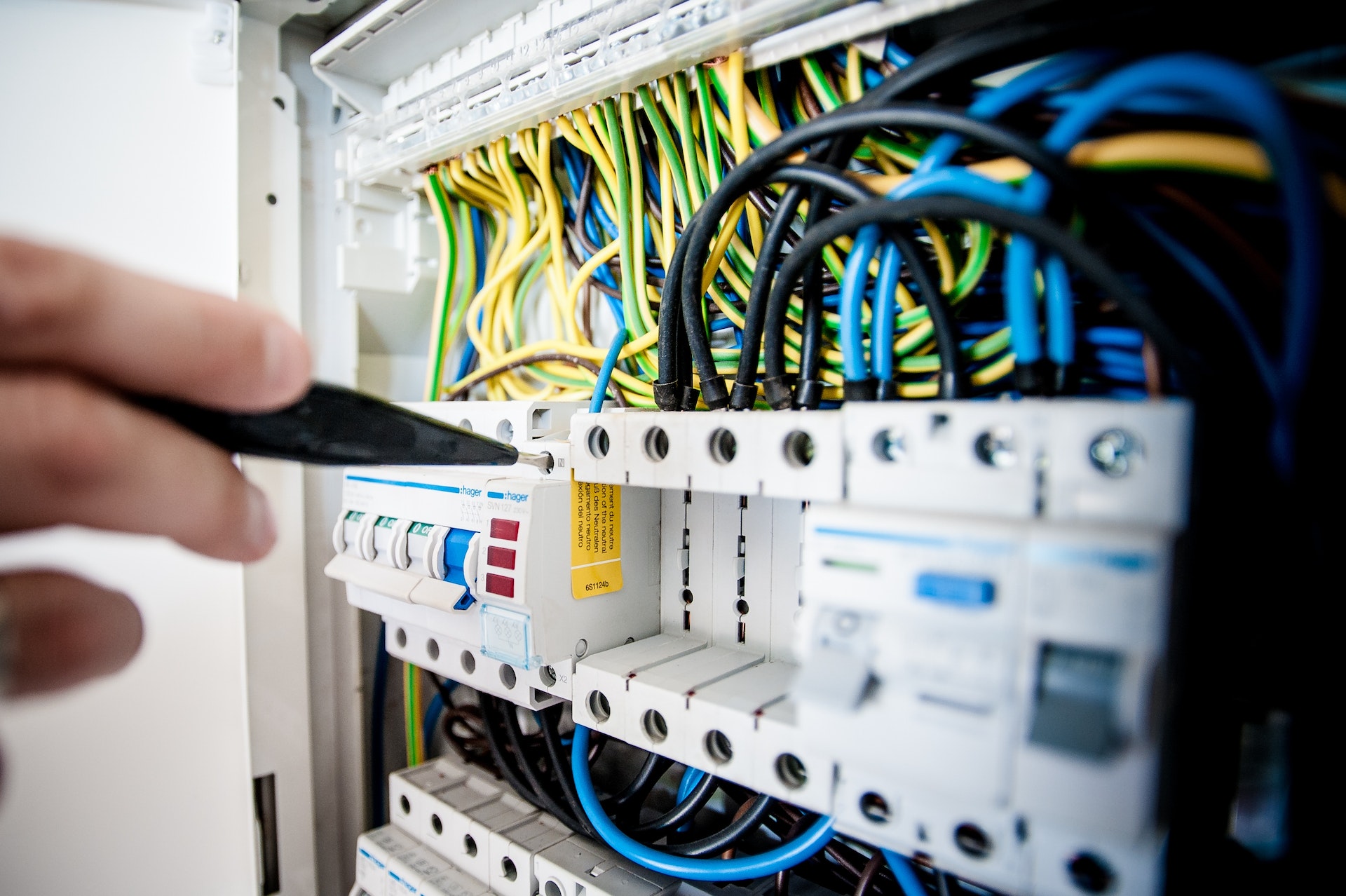

Electrical engineers could design several different types of protective system and technique that reduces risks of electrical system in case of faullire and guarantee protection of workers, plant and premises from electrical hazards during operation

a. Fuse

A thin strip of conducting wire which will melt when an excess of the rated current passes through it. It breaks the circuit, thus providing protection against faults and current overloads. Protection is limited to equipment and installations only from overheating and fire so it not at all effective with electric shock due to the time that it takes to cut the current flow

b. Isolation

Making the circuit dead by ‘switching off’ the current, thus cannot be accidentally re-energised. It is marked as stoper between the equipment and the electrical power supply. Which only an authorised person should be able to remove. Usually required to ensure safety during the work process and must be locked/unlocked by authorised person who checks the electric system before disconnect/re-connect to power supply

c. Reduced low-voltage systems

In sever working conditions (wet, high humidity) or high intense usage of equipment, reduced voltage systems should be used, so even in worst case scenario the worker will suffer a reduced electric shock, thus reduce the sever outcome. Battery (cordless) operated hand tools is preferable to be utilised as a low-voltage equipment

d. Insulation

Insulation material (thermoplastics) covers the live conductor, often accompanied by the enclosure to prevent reaching out by people. Having more advantage than fuse, it provide people with protection against electric shock, in addition to protection of all consequences of short circuit (fire and explosions). Although being effective, if failed, electric shock, fire, explosion or instrument damage may occur

e. Double insulation

Consist of two independent layers of insulation over the live conductors for double protection, although a one layer in separate is suitable and fair to insulate the electrical equipment safely. If accidentally a live part becomes exposed, it still able to prevent internal fault condition from making any outer part live, thats why it is used in hand and non-hand held portable appliances

f. Residual current devices

It is the best form of protection against electric shock since it is very sensitive to differences of flowing current, it automatically cut the supply to the equipment between the live and neutral power lines even with few milliamperes difference occurs in a very short period of time ( 40 milliseconds or less at a residual current of 250ma )

2. Major advices to apply safety use of electrical energy

1. Properly designed, installed and maintained electrical equipment and system to meets requirements of its purpose safely

2. The better design, the lower proportion of risk of electric shock, burns, fire or explosion while using

3. Protect cables and equipment against mechanical damage.

4. Ensure effectiveness of insulation specially in damp weather

5. Prime assessing of workplace before approaching any electrical source

6. As much as possible avoid live working particularly during fault finding

7. Provide safe workspace,, access and lighting to work safely.

8. All electrical works shall be carried out by competent persons

9. Regarding adverse weather conditions:

a) Flamable and explosive environment ensure suitablity of used equipment

b) Used equipment shall be certified explosion-protected equipment

10. Further safe precausions of protective systems:

a) Lock out tag out (loto) all switch disconnectors in off position

b) Properly design electrical system enabling isolation of circuits and equipment when required

c) Suitably locate and arrange switch disconnectors so that circuits and equipment can be isolated seperately

d) Clearly marked device used for isolating circuits

e) Use drawings and records to identify relationship between equipment and their control switchs